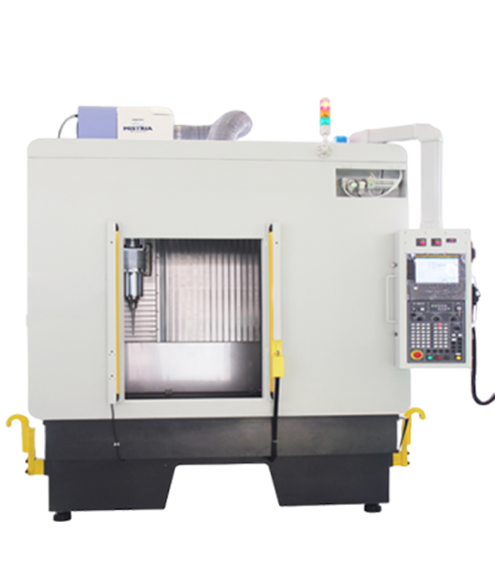

Model | i-movacMA T(双主轴换刀) | i-movacM T(双主轴不换刀) | |

High-Pressure Pump (Cleaning Pressure) | 50MPax20L/min | ||

Pressure Adjustment Method | Smart pressure adjustment system | ||

Stroke (mm) | X=700 Y=500 Z=500 | X=700 Y=500 Z=500 | |

Maximum Travel Speed | 48m/min (X,Y,Z) | ||

Repeat Positioning Accuracy | ±0.05mm | ||

Maximum Spindle Speed | 500r/min | ||

Tool Magazine Capacity | 6 Units | None (No tool change) | |

CNC Specifications | FANUC 0i MF PLUS | ||

Filter System | Simple filter (#40) + Bag filter (10μ) + Bag filter (5μ) | ||

Standard Configuration Accessories | CNC rotary table, oil-water separator, mist collector, indoor lighting | ||

Weight | 6.5Ton | 6.5Ton | |

Equipment Dimensions (mm) | Width 2000 × Length 5000 × Height 3000 | Width 2000 × Length 5000 × Height 3000 | |

Capacity | 41KVA | ||